by Richard Creaser copyright the Chronicle 9-26-2012

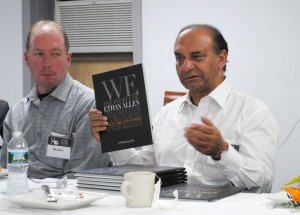

ORLEANS — As Ethan Allen Manufacturing Inc. entered its eightieth year in business, company Chairman, President and CEO Farooq Kathwari felt it only appropriate to celebrate the occasion in Vermont, where it all began. Mr. Kathwari’s first stop was at the Beecher Falls facility, followed by an afternoon reception and tour of the Orleans plant on Tuesday.

“To be around for 80 years, either by plan or by accident, you have to reinvent yourself,” Mr. Kathwari said. “One challenge was to figure out how to maintain manufacturing in the United States in the face of the pressure of globalization and commoditization.”

Ethan Allen has weathered two great economic calamities: the Great depression of the 1930s followed by the Great Recession of 2007. It has done so by rising to the challenge and adjusting to changing market conditions, Mr. Kathwari said. The most recent challenge involved rethinking the model used in manufacturing in America.

Where once assembly lines churned out hundreds of identical pieces, one after the other, a visit to the workshop floor today reveals dozens of different models and styles of furniture in various stages of assembly. The change reflects a recognition that American-produced goods cannot compete with the low-cost mass manufacturing capabilities of Southeast Asia.

To meet that challenge, Ethan Allen adopted a custom order model. Rather than mass producing items in anticipation of sales, the plants would be retooled to respond to specific orders from customers.

“Each piece that comes off the line is already sold,” said Don Garrett, vice-president of manufacturing. “When we make each piece we know the name of the person it is going to. That creates a powerful connection between us and the consumer, because it isn’t going to go into a warehouse on top of a pile of stuff.”

Switching to a custom model realizes certain efficiencies that enhance the company’s bottom line, Orleans plant controller Chet Greenwood said. No longer is the company paying to build and then warehouse items in the hopes of selling them.

“Everything is built to order and then shipped to the end consumer,” Mr. Greenwood said. “Inventory that sits in a warehouse is dead inventory, and dead inventory hurts your bottom line.”

Today’s Ethan Allen is supported by the three pillars of investment in infrastructure, the production of high quality goods and a high quality of leadership, Mr. Kathwari said. All three elements have proven critical in ensuring the company’s success through difficult times.

At the core of those three elements are the people behind the products, Mr. Kathwari said. Maintaining a good relationship with the workforce involves applying a long view of the company’s future.

Ten to 15 years earlier the quality of production had slipped at the Orleans plant, Mr. Kathwari told an assembly of the factory’s 360 workers on Tuesday afternoon. Uncertainty about the future of the plant was doubtless a contributing factor, he said.

“If people are worried about the plant closing it affects you,” Mr. Kathwari said. “If affects you mentally and it affects you financially. I understand that.”

Since the change to custom order production, the quality of work coming out of Orleans is the best on the East Coast. That is a reflection of confidence in the company and the direction it is heading, Mr. Kathwari said.

“Every time I come here I see people I have seen and known for many, many years,” Mr. Kathwari told the Chronicle. “No company can afford to lose that level of experience and knowledge. Longevity is fostered by treating them with the dignity they deserve whether it is through better working conditions or a decent wage. It isn’t rocket science.”

Operating within the constraints of the American corporate climate is not an easy task, Mr. Kathwari said. Corporate taxes are among the highest in the world, while labor and energy costs are equally troublesome. Overcoming these barriers is something that Ethan Allen has sought to do internally.

“If we are to wait on the state or the country to come to our aid we will be waiting a long time,” Mr. Kathwari said. “So we do what we must to ensure that we are as competitive as we can be.”

Ethan Allen’s Vermont operations are almost entirely oil free, Mr. Kathwari said. A cogeneration facility at the Beecher Falls plant provides electricity and heat that supplies the majority of the needs of that plant. Wood waste generated both on site and trucked in from Beecher Falls provides heat for the Orleans facility.

“Two years ago we used 250,000 gallons of oil to heat this plant,” Mr. Greenwood said. “Last year it was none. We won’t always have that mild a winter, but we are taking steps to keep the costs we can control under control.”

Today nearly 70 percent of Ethan Allen’s products are manufactured in the United States. Though outsourcing remains a prickly issue, it is a necessary evil to balance the profitability of the company, Mr. Kathwari told the Orleans plant workers.

“If it wasn’t for that plant in Mexico or that plant in Honduras, Orleans would be a very different place today,” Mr. Kathwari said. “We would have no profits if we manufactured everything in the United States.”

One promising trend is that, even as Ethan Allen has withdrawn its presence from Asia, it is generating business in the Far East. The company now has 73 retailers in China and furniture manufactured here in Orleans is being shipped to consumers in China, Mr. Kathwari said.

“Who would have imagined that five years ago?” Mr. Kathwari asked.

The margins on American manufactured furniture remain slim, but improved efficiencies have helped to increase profitability at the Orleans plant by 30 to 40 percent over the last two years. Switching from two shifts to one has helped increase that profitability, Mike Worth said. He is the regional operations manager for the Orleans and Beecher Falls facilities.

“We got rid of the second shift because of all the overhead costs that go along with it,” Mr. Worth said. “We’re doing more volume now on one shift than we used to do on two.”

The investment in specialized computer numerically controlled (CNC) machines has allowed the plant to quickly adapt from one product line to the next. While it is still necessary to switch out the cutting tools and drills to match each piece, the process has inherent efficiencies and greater precision.

“We used those lean years to invest in new technology to help us get to that next level,” Mr. Worth said.

Several area legislators took part in the tour of the factory on Tuesday. Representatives Duncan Kilmartin, Bob Lewis, Mike Marcotte and Vicki Strong joined Senator Bobby Starr in commending Ethan Allen for its continued commitment to providing employment for their constituents.

“I know you provide a lot of good jobs for a lot of good people,” Mr. Starr told Mr. Kathwari. “I know that if we work together we can keep this place going for another eighty years.”

contact Richard Creaser at [email protected]

For more free articles from the Chronicle like this one, see our Featuring pages. For all the Chronicle’s stories, pick up a print copy or subscribe, either for print or digital editions.